SOFT PLASTIC LURE MAKING MOLDS, PLASTISOL, AND SUPPLIES

LURE MOLDS

Which Mold Type Is Best For YOU - THEY ALL CATCH FISH

FX MOLD - Silicone Open Pour Molds

InjeX - Machined Resin Injection Molds

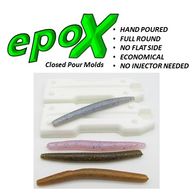

EpoX - Closed Pour Cast Resin Molds

Silicone open pour molds are far the most popular, most economical, and easiest to use molds. They produce high quality lures quickly and with little to no waste. Open pour molds allow two and three color lures to be produced much easier than with other molds. Open pour molds are receptive to a much large range of resin hardness levels than other types of molds. No injector or special tools are needed. Simply heat resin and pour into the mold. The only downfalls to open pour molds are they always have a flat side to the lure. On most lures this flat side is designed into the belly or back of the lure to give the lure a natural look. The second drawback to open pour molds is there is a limit to how thin lure features can be made making this type of mold unsuitable for lures with small and thin appendages.

EpoX - Closed Pour Cast Resin Molds

InjeX - Machined Resin Injection Molds

EpoX - Closed Pour Cast Resin Molds

Some simple lure designs allow the use of closed pour molds. These lures are usually soft plastic stick bait type lures. These molds provide the full three dimensional appearance as with injection molds with the ease of use of open pour molds. No injector is needed. Simply pour the lure from the top until the mold is full. Laminated two color lures as well as separate head or tail colors can easily be made.

InjeX - Machined Resin Injection Molds

InjeX - Machined Resin Injection Molds

InjeX - Machined Resin Injection Molds

Machined resin injection molds produce a high quality fully three dimensional lure using a two piece mold and injector. These molds are capable of producing very complex and highly detailed lures. Single cavity and multiple cavity versions are available. Two color laminated baits can be made using a dual color injector on many of these molds. There can be limitations to using these types of molds on softer resin compounds as the softer resin tends to shrink more while cooling.

Tube Dip Molds

Tube Dip Molds

InjeX - Machined Resin Injection Molds

Simply dip these tube rods into molten resin and allow to cool. After cooling remove from rod and slit the tails. Most lures require two to three dips of all or part of the rod to achieve the desired wall thickness. Two color lures are easily made as well. Most tubes are made using X-Firm resin hardness.

Aluminum Molds

Tube Dip Molds

Aluminum Molds

Most of the InjeX series of molds are available in machined aluminum versions as well. Same lure and mold design, just machined from aluminum instead of resin. The benefits of aluminum are faster heat transfer for more rapid cooling and higher resistance to scratching.

Custom Molds

Tube Dip Molds

Aluminum Molds

FusionX Fishing can work with you on designing and developing custom lures and molds using any of our current methods: OPEN POUR SILICONE, CLOSED POUR CAST RESIN, MACHINED RESIN, MACHINED ALUMINIUM. We can help with rapid prototyping of lure designs as well. Molds for lead and silicone lures are also available.

Featured Products

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.